(~ 30 Nov. 2017.) I am backing up to tell about some of the issues we had getting Drummer ready to leave Fort Lauderdale. We had just returned from a Thanksgiving with my family up in Kentucky and had tickets to fly out to Seattle for Christmas with the grandkids on the 15 of December. Our slip rental in Lauderdale was up at the end of December and our plan was to fly back from Seattle on the 27th, gas up the boat, and sail south for Key West on the first of January.

Something no boater ever wants to see, oil in the bilge, broken bolts, and a sheared key. (Fortunately, Drummer has an ‘engine bilge’ that is separate from the main bilge, so absolutely no oil was accidentally pumped overboard.) I found the items shown in this picture, along with a small amount of what appeared to be transmission oil, in the engine bilge while preparing to go out for a day sail. Of course that plan got scrapped.

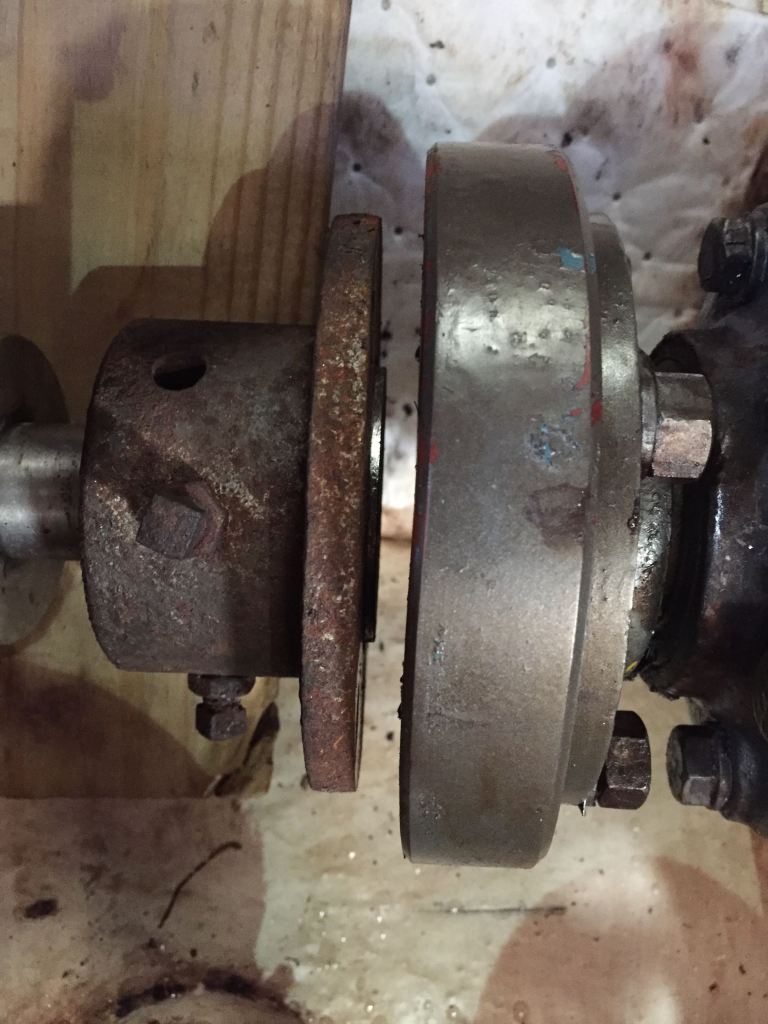

Closer inspection showed that the flex coupler was only hanging together by a single bolt. A flex coupler allows a rigidly mounted engine to connect with an also rigidly constrained rotating propeller shaft by allowing a very, very small amount dis-alignment between the two. And, by ‘small’ I mean on the order of thousandths of an inch in each of the left-right, up-down, as well as in the straight direction. A small amount of transmission fluid was dripping from the seal at the back of the transmission. In addition to all of that I found that one of the forward motor mount bolts had vibrated loose. Having never worked on anything relating to marine propulsion, I knew I was in over my head and called in an expert. There are lots of experts in Lauderdale. The picture below shows the flex coupler (the light grey thing on the right) connects to the shaft coupler (the rusty dark grey thing on the left.) Once we removed the final bolt holding them together, we could see that the shaft keyway was damaged. The oil was coming from the rear seal on the transmission. My expert was telling me that the engine and shaft were very badly out of alignment – hence the loose motor mount and that in order to repair the shaft and replace the transmission seal, the propeller shaft would need to come out.

I was thinking that we were going to have to do another haul out at the cost of at least another boat-buck (one boat-buck is $1,000) plus the cost to repair the shaft. Plus the cost to replace the seal. I was starting to go into sticker shock. Again. But my expert told me that it was possible to have a diver remove the shaft while the boat was in the water. And it would only cost about $150. So, that is what we did.

But, if you think it was that easy, you, like me, don’t know anything about what it is like to work on a boat. Nothing is that easy. Drummer has a type of propeller called a MaxProp and in order to get the shaft out the MaxProp has to come off. A MaxProp is a wonderful invention for sailboats. When the boat is sailing with the engine off, the blades of the MaxProp fold or ‘feather’ so that the propeller does not slow the boat. When the engine is running and the boat is being propelled forward, the propeller blades rotate to give the optimum blade pitch to drive the boat forward and when the boat is in reverse, the propeller blades rotate in the opposite direction to give the best blade pitch for reverse. The MaxProp is a wonderful piece of engineering, filled with gears and cogs. And very expensive. On the order of five boat-bucks. And, in order to remove Drummer’s shaft, that marvelous piece of engineering had to be taken apart under water. A total of 10 tiny allen screws, each held in place with tiny cotter pins, had to be removed. The body of the MaxProp is like a clam shell and inside are all the little gears and cogs that make the blades rotate.

The diver had the MaxProp off in less than an hour. Not a single allen screw or cotter pin or gear or propeller blade was lost. It was amazing.

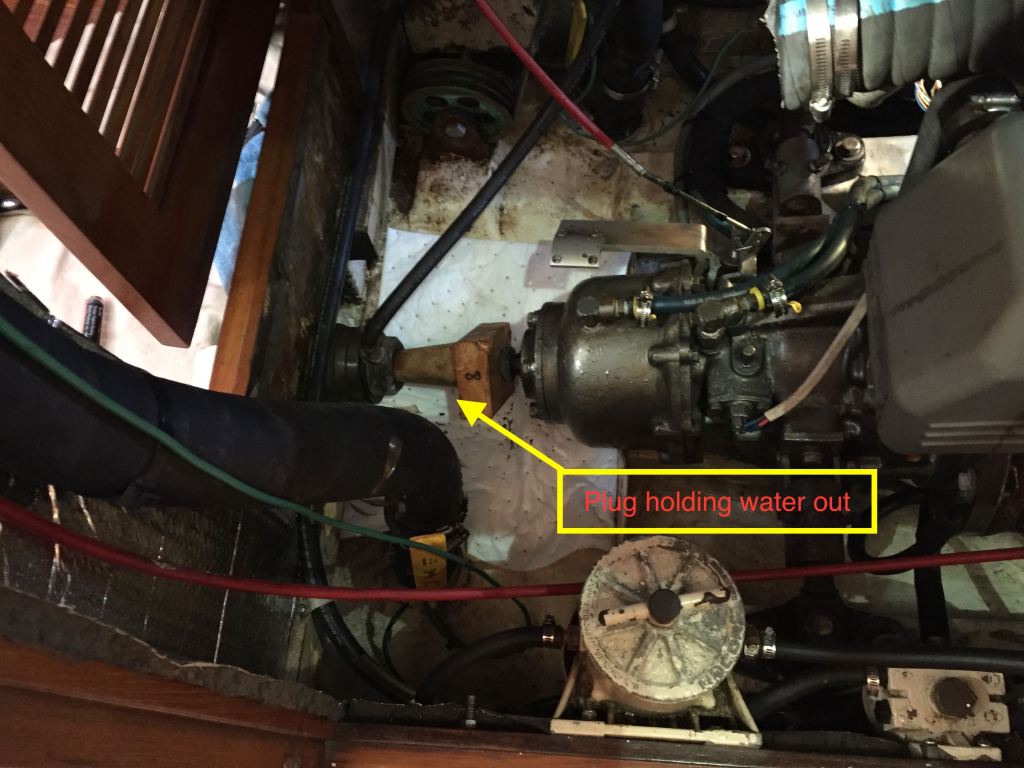

Then the shaft could come out. That means that there would be a roughly one inch diameter hole in the bottom of the boat that is still in the water. When the diver pulled the shaft out we immediately plugged the hole with a wooden plug braced it against the rear of the transmission. The picture below shows the plug.

The shaft was sent to a machine shop and unfortunately was not salvageable. A new shaft would have to be machined and that would take at least a week. In the meantime my expert and I replaced the shaft seal on the transmission. I mainly held the flashlight and asked questions. Fortunately, he didn’t mind and appreciated the company. And the illumination. We got the new shaft back just two days before Jan and I were scheduled to fly to Seattle for Christmas. We were able to schedule the diver for the next day. He arrived at the agreed time and, in another feat of underwater magic, reassembled the MaxProp without losing a single cotter pin. That just left it to my expert and I to attach the new flex coupling to connect the propeller shaft to the engine. Since it was late in the day we decided that the final engine alignment could wait for the morning.

On the last day before Jan and I were to leave my expert and I started working on aligning the engine to the shaft. I have never seen this done so let me explain it a little. The engine is very heavy and is mounted on four motor mounts. Each corner of the engine can be raised or lowered by rotating adjusting nuts a fraction of a turn at a time. After each adjustment the gap between the shaft coupler and the flex coupling is checked with a feeler gauge. (A feeler gauge consists of very thin sheets of steel of a known thickness). The idea is to rotate the motor mount adjusting nuts on each corner of the engine up and down and, if necessary loosen the mounts use a pry bar to rotate the engine right and left, until the gaps between the shaft coupler and the flex coupler at the top, bottom, left, and right were all within 3 one-thousands of an inch of each other. Ideally you would want them to be exactly the same, but 3 one-thousands of an inch is considered ‘close enough’. After working at this task nearly a full day we discovered that the forward motor mounts were the wrong size. There was simply no way to align the motor with the shaft with the existing motor mounts. The front of the engine could not be lowered enough. This, it turns out, was probably the root cause of all of the issues. At eight p.m. we gave up.

Jan and I left for Seattle the next day leaving Drummer partially assembled. Changing the mounts and re-aligning the engine and propeller shaft would have to wait until we returned after Christmas. Oh! And my expert would not be back until mid-January. I would be on my own. More in Part 2.