( December 2017) We returned from Christmas with Jess and Rob and the grandkids on the 27th. I had done some research and found that I could order thinner motor mounts. They were waiting for me when we arrived back in Lauderdale. Thinner motor mounts allowed the front of the engine to be lowered sufficiently so that near perfect alignment could be achieved. Oh! And one more thing – my expert was gone on vacation until the end of January. I was going to be on my own.

Unlike everything else I had ever worked on (cars), the engine in a sailboat is adjusted to align with the shaft. The shaft is held rigidly by the strut and by the shaft log (free to rotate, of course) and the engine must be moved so that it is in perfect alignment with the shaft. Somehow the previous owner had installed the new engine with front motor mounts that were too tall by about an eighth of an inch. That’s 125 thousandths of an inch where the maximum allowable is just three. That caused the shaft to bind and damaged the seal as well as vibrated the motor mount loose.

It took me about four or five hours to install the new front mounts. Jacking up a 500 pound engine using three of the four motor mounts to give room enough to remove the fourth takes a while. Then you repeat the process to remove the other mount. Then it was time to align the engine. Fortunately, I had watched my expert do it. And, I had watched YouTube. It was a piece-of-cake. I had the alignment to within one one-thousandths of an inch in all directions.

Then it was time to re-fill the transmission with oil. I was in the home stretch. We might even get out of Lauderdale by the first of January when our slip lease ended. That’s when I saw the new transmission fluid dripping out of the back of the transmission.

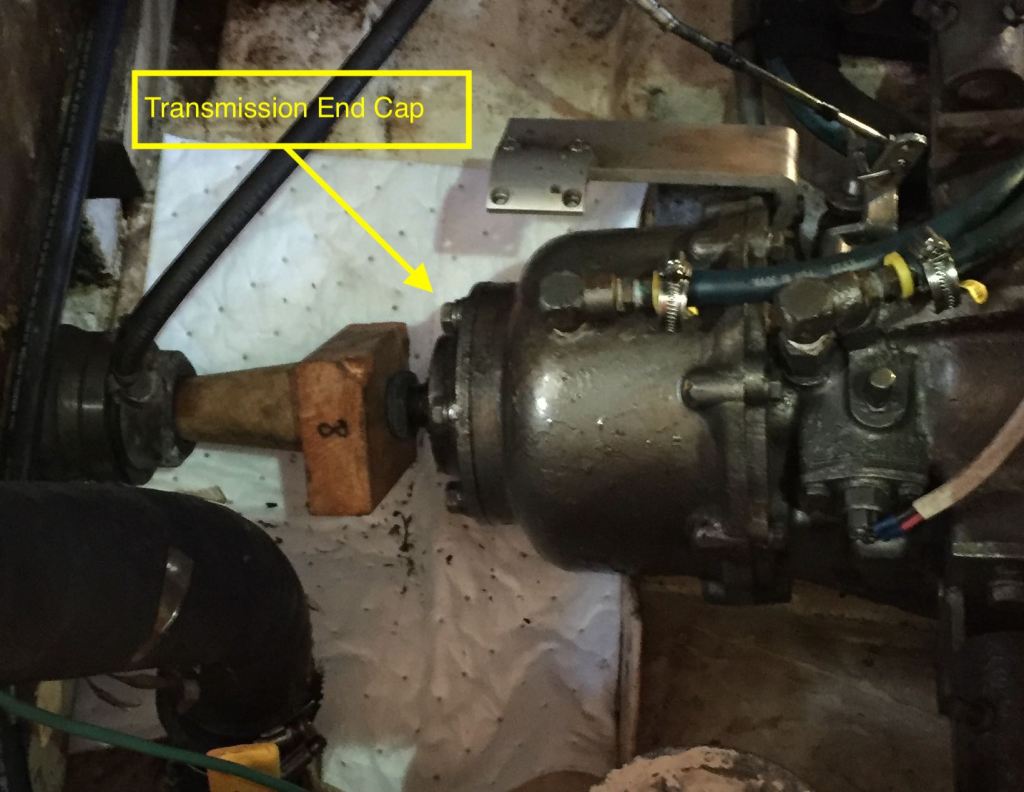

It did not look like it was coming from the new seal. It seemed to be coming from the transmission end cap. I emptied the new oil, disconnected the shaft, removed the flex coupler and pulled off the transmission end cap. A picture of the transmission end cap is below.

Along with the new shaft seal, my expert had installed a new gasket on the transmission end cap. Now, you might think that it wouldn’t matter how that gasket was installed as long as the five mounting bolts went through the five holes in the gasket. You would be wrong. The gasket, it turns out, has a left and right side. And on one side there is a tiny, tiny hole that allows transmission fluid to be pumped up to lubricate the seal. If, however, the gasket is installed backwards, the tiny, tiny hole allows transmission fluid to be pumped right out of the case and into the bilge. I was lucky that I found the leak before starting the engine. But, I had destroyed the new gasket which had been painstakingly glued to the freshly cleaned transmission end cap and case. And, it is now 6:00 pm New Year’s eve. The boat parts store is closed. Almost everything else is closed. Except AutoZone. They were open until 8:00. Although they didn’t have an end cap gasket for a Velvet Drive marine transmission, the did have a roll of gasket material and I could cut my own.

New Year’s Day (or maybe the day after) I contacted my slip landlord and told him my sad story. He was super sympathetic and agree to let me stay for a few more days to sort out my remaining issues. I offered to pay for an additional week or even a month, but, he was willing to let me slide. I think he felt sorry for us.

I got the new gasket cut and fit (making sure that the tiny, tiny hole was on the correct side) and re-installed the transmission end cap and flex coupler. I checked the alignment (still dead on) and slowly refilled the transmission oil. There were no leaks. It was time to start the engine for a static test with the boat tied to the dock.

With the engine slowly idling I put the transmission into forward and reverse, checking for leaks at every step. Not a drop. So far, so good. I gave the engine a few more RPM’s and then I noticed something odd. Drummer didn’t seem to have much thrust. It barely seemed to take the slack out of the dock lines. I gave it more RPMs. Was the transmission slipping? Was it something else? I was almost ready to go into a full ‘Chevy Chase’ (as in “Christmas Story”) melt down. “Low life, snake licking, dog licking, sack of monkey shit!”. It was too bad that I had already paid my expert. And that he was away on holiday.

But, Lauderdale is full of experts. And Captain John is one of the best of the best. He came over over and I recounted all that I had been through with the transmission, removing the shaft (under water), the MaxProp, the motor mounts, and the incorrect gasket installation.

“What was the setting on the MaxProp?”, he asked.

“Setting?”, I said. “The diver installed it. Under water. We left it as it was when we took it off.”

“I think that is your problem”, he said. “It is super easy to get the propeller blades out of alignment even if you are doing it on dry land. Let’s call the diver back and get him to pull the prop off and make sure that we explain exactly how it needs to be put back on.”

I think that it took a few days to get the diver back. In the meantime I downloaded a complete instruction manual on the set up and adjustment of the MaxProp. I studied it and relayed it, in detail, to the diver. He re-installed the prop without losing a single screw or cotter pin. I started Drummer and put her into gear. The dock lines strained. At last, we were ready to go.

We left our slip the next day. Down the New River, past the four bridges to a marina just inside the Everglades pass and spent the night. The following day we motored out into the Atlantic and turned left, heading to Key West.